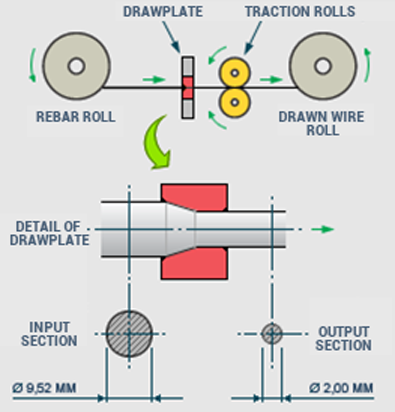

WIRE-DRAWING PROCESS

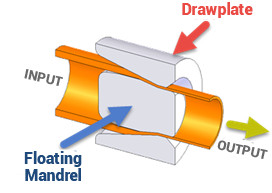

The wire-drawing process consists of reducing the cross section of a material bar, applying traction to it against a matrix (drawplate or drawer), thus ensuring more precise tolerances when compared to the process of extrusion, which, on its turn, pushes the material against the matrix.

ADVANTAGES: WIRE-DRAWN vs. EXTRUDED MATERIALS

• Dimensional precision: the wire-drawing process maintains the matrix dimensions, ensuring great dimensional precision that may reach hundredths of millimeters;

• Surface finishing: When added to the conditions of facility in cold plastic deformation of the material to be drawn, good matrix finishing and correct lubrication, more perfect surfaces, with low superficial roughness, are obtained;

• Mechanical properties: for being cold drawn, the hardening grants the product higher mechanical property and more uniformity than the extruded product;

• Deformation rate: in case of deformation rate higher than the one specified by the alloy, it is possible to relieve the tension between steps and draw in more than one step.

For production in multi-spindle lathes (both mechanical and CNC), movable head lathes and automatic lathes, the use of wire-drawn materialis indicated. This material ensures better bar fastening by clamps, reducing issues with vibration, roughness and dimensional variation.

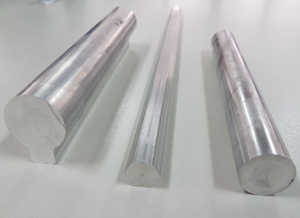

An example of wire-drawn material is aluminum, which, thanks to having a high plastic deformation capacity, allows reducing the profile size, whether it is hexagonal, round, square, tubular or has any special profile.

Aluminum Bars

Na Altref, the Aluminum division from Samot, conducts the wire-drawing process for different aluminum alloys, such as 2011-A, 1050, 6026 and 6351. Due to the major effort in the material conformation during the wire-drawing process, the material has its straightness compromised at times. For this reason, the components go through a second process, named “straightening”. This process consists of passing the drawn bars through a machine with several sequential rolls, with adequate profiles and pressures for the size and type of material to be processed.

Straightener of round materials

fter this final process, the product is able to be packaged and shipped with assured quality. With this and with the help from Altref, the SAMOT group can directly sell wire-drawn bars and profiles for anyone who needs raw material with quality finishing combined with reduced tolerances.