TOOLS DEDICATED TO DEVELOPMENT

Throughout the project development, it is necessary to have support from specific areas so it is conducted with excellence. In the industry, this is not different. For executing a machining resource as planned, Tools is one of the most requested areas to meet the project’s needs.

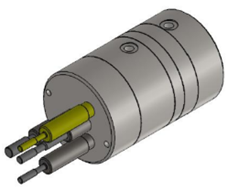

It is responsible for executing different customized components that are necessary during the development. The Tools area executes the entire construction of fastening devices, machine elements, special tool supports, measuring devices, poka-yokes, among others.

To do this, it is necessary to have the support from a project area that understands the actual need for applying the devices and what the machine elements requested are. This way, every information can be aligned with innovations in the market. After all, there will be new tool steels, new concepts for constructing devices and leading-edge machining tools, among others.

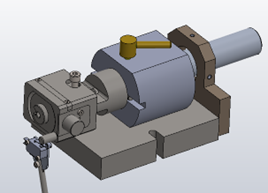

During the development of a product, in partnership with engineers who conduct the machining process project, it is possible to execute simulations of machining and movement of devices to be built, checking still in this initial step possible faults that would certainly cause delays, unexpected events and product quality issues.

Combining these two areas, Projects and Tools, the best results will be achieved concerning deadline, cost and quality of deliverables.

To do this, Samot has its own Projects and Tools structure, using state-of-the-art software and CNC machine tools dedicated exclusively to machining elements in different formats.

Our Tools area also makes internally clamps for mechanical multi-spindle lathes, sliding head lathes, automatic lathes, jaws for CNC lathe faceplates and extrusion matrices, for example. This offers more speed to the development of our items.