Thermal Treatments in Aluminum Alloys

Thermal treatments in aluminum alloys are conducted to improve the mechanical properties of the material, through change in the structure. Alloys that can undergo thermal treatment are the ones from series 2XXX, 6XXX, 7XXX and a considerable part of series 8XXX. In this article, we will better understand about some of the main options of treatment for these materials: solubilization, aging and annealing.

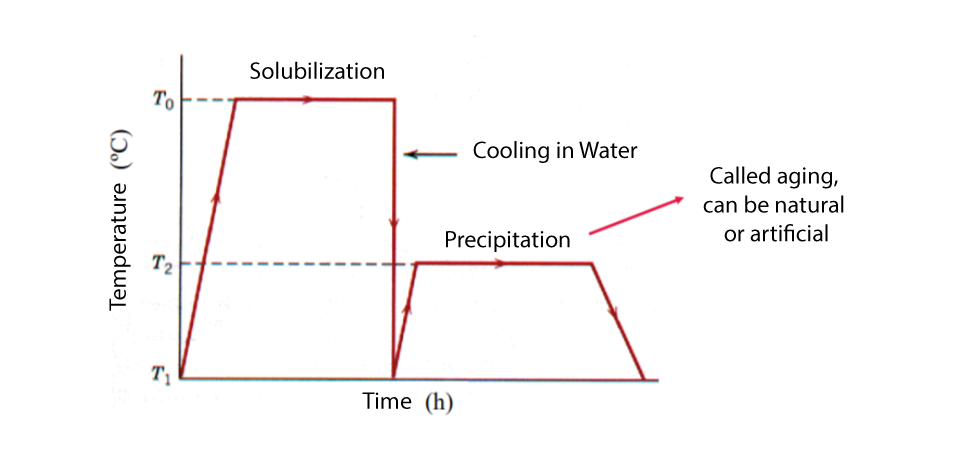

The first treatment to be described is solubilization, which consists of heating the material at a temperature near its melting point for a certain period, increasing the diffusion of the alloy’s elements, such as copper, zinc, manganese, and silicon, for example, improving their dissolution in the aluminum matrix. After the waiting time, the material is suddenly cooled down, usually in water tanks that are suitable for this operation.

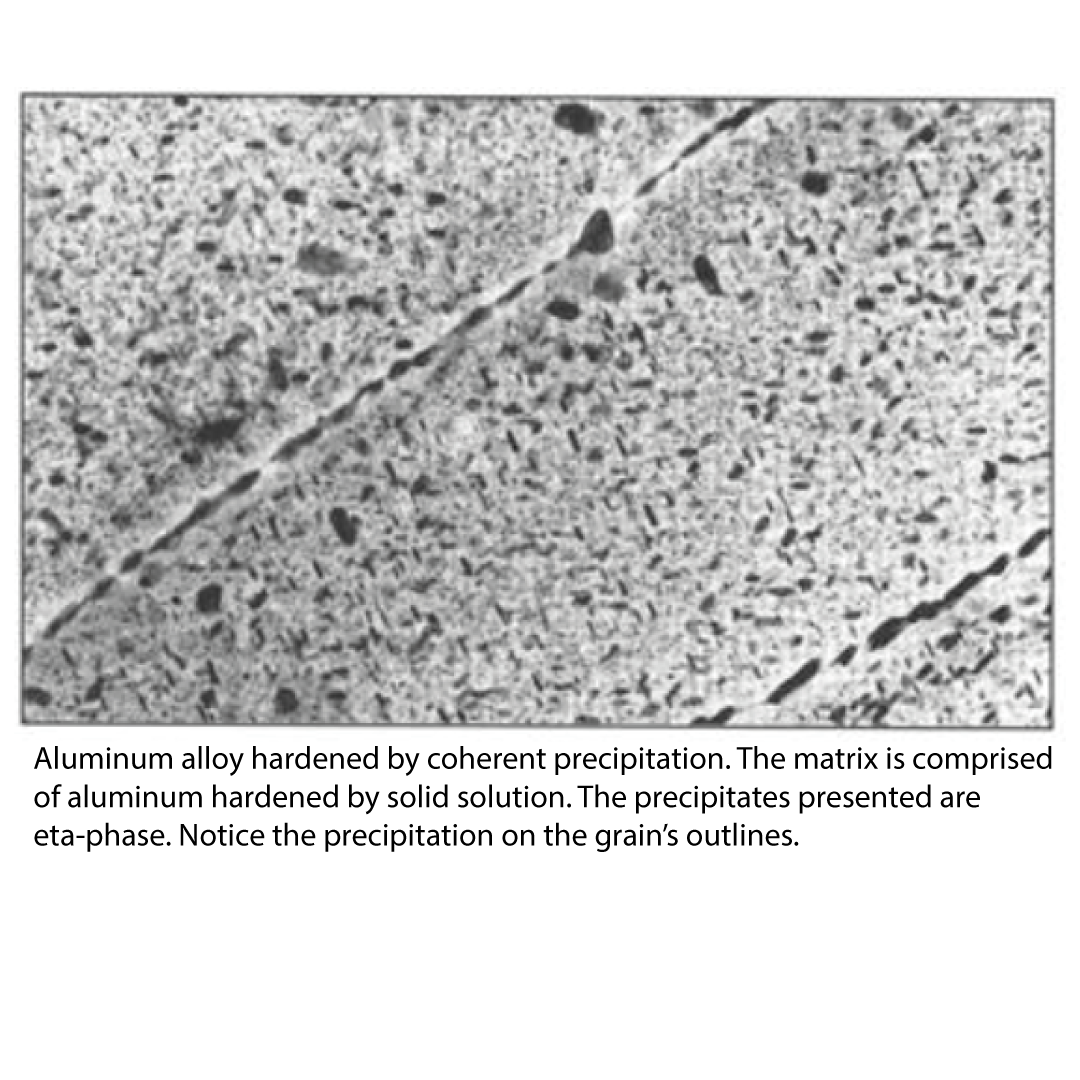

These dissociated elements work as barriers to the movement of dislocations, hardening the alloy, but such precipitations need to be sufficiently small to maintain consistency with the matrix, usually obtained through the later process of aging, which may be natural or artificial.

The second thermal treatment is aging – in natural aging, the movement of precipitates is slower than in artificial aging and occurs at room temperature.

Artificial aging occurs at a higher temperature, is conducted in furnaces, and it is possible to achieve maximum hardness for a certain time of treatment. If the artificial aging time or temperature are not strictly followed, the materials can have their mechanical properties affected. In artificial aging, the cooling process is slow and conducted open-air.

Another thermal treatment for aluminum is annealing. In this treatment, the material is produced as usual and, at the final step of the process, it is submitted to heating in furnace, increasing its temperature to a near solubilization temperature. The material must be maintained at this temperature for a certain period of time and, later, cooled on air. Annealing is generally used for materials that will undergo mechanical conformation, such as forging or reverse extrusion. Thus, all parameters from the aging or annealing process must be limited to a safe level and the controls must be robust to ensure the quality and integrity of the alloy.

Samot, through its aluminum division ALTREF, conducts all types of thermal treatments in aluminum alloys and invests in technology and process controls, aiming at quality and the best service for the increasingly demanding requirements from different markets.