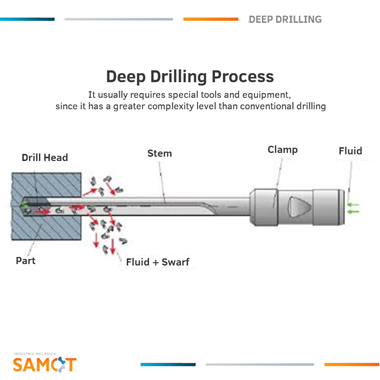

DEEP DRILLING PROCESS

The drilling process is widely used in the manufacturing industry, responsible for approximately 30% of all machining operations. Despite approximately 60% of the drilling applications in the mechanical industry being of short drills, with depth up to 2.5 times the diameter of the tool, many operations require depths greater than 5-fold the diameter.

While normal techniques produce holes with depths rarely reaching more than 5-fold the diameter, in deep drilling it can reach up to 150-fold the diameter of the hole.

This type of operation usually requires the use of special tools and equipment. Deep drilling has a greater complexity level than the conventional one due to the critical machining conditions in which it is developed. Such conditions include the difficulty of formation and flow of chips, the scale length of the tool, the quality of the surface, and the geometrical and hole form tolerances.

Key characteristics of deep drilling:

• High capacity of advancement and depth;

• Drilling tolerance between IT 6 - IT 9;

• Good drilling geometry;

• Good superficial finishing;

• Small deviation.

In order to meet the demands of the market, SAMOT uses different equipment models to perform the deep drilling processes, using several tools (gun drill bits and twist drill bits, for example).

Deep drilling is yet another key feature at SAMOT to meet the market needs in several segments, always focusing on the result sought by the client.